Yanliang Zhang, associate professor of aerospace and mechanical engineering at the University of Notre Dame, and collaborators Alexander Dowling and Tengfei Luo, have developed a machine-learning assisted superfast new way to create high-performance, energy-saving thermoelectric devices.

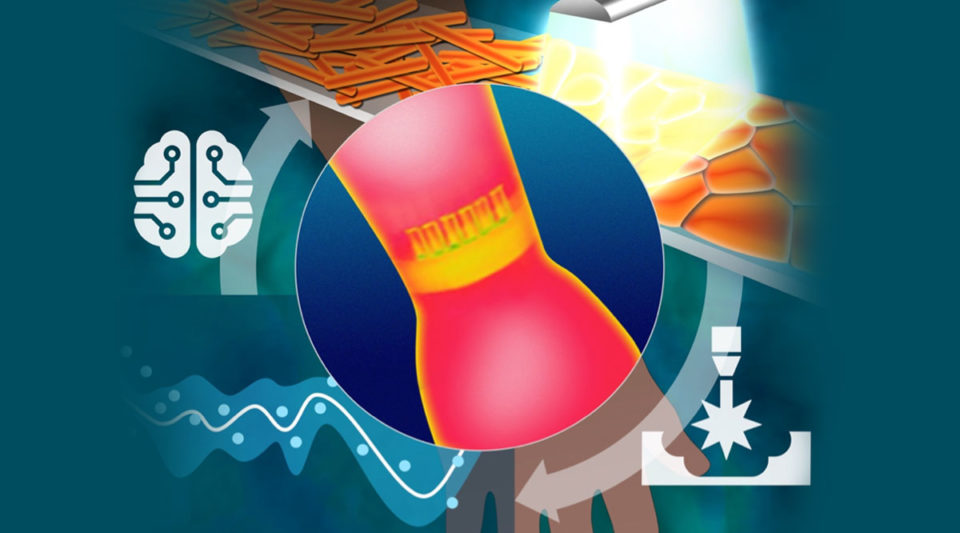

The novel process uses intense pulsed light to sinter thermoelectric material in less than a second (conventional sintering in thermal ovens can take hours). The team sped up this method of turning nanoparticle inks into flexible devices by using machine learning to determine the optimum conditions for the ultrafast but complex sintering process.

The achievement was just published in the journal Energy and Environmental Science.

Flexible thermoelectric devices offer great opportunities for direct conversion of waste heat into electricity as well as solid-state refrigeration, Zhang said. They have additional benefits as power sources and cooling devices — they don’t emit greenhouse gases, and they are durable and quiet since they don’t have moving parts.

Despite their potential broad impact in energy and environmental sustainability, thermoelectric devices have not achieved large-scale application because of the lack of a method for fast and cost-effective automated manufacturing. Machine-learning-assisted ultrafast flash sintering now will make it possible to produce high-performance, eco-friendly devices much faster and at far lower cost.

“The results can be applied to powering everything from wearable personal devices, to sensors and electronics, to industry Internet of Things,” Zhang said.

“The successful integration of photonic flash processing and machine learning can be generalized to highly scalable and low-cost manufacturing of a broad range of energy and electronic materials.”

Zhang is principal investigator of the Advanced Manufacturing and Energy Lab at Notre Dame. Alexander Dowling, assistant professor of chemical and biomolecular engineering, and Tengfei Luo, Dorini Family Professor for Energy Studies — both experts in machine learning — contributed to this research, along with Ph.D. student Mortaza Saeidi-Javash (now assistant professor at California State Long Beach), Ph.D. student Ke Wang, and post-doctoral associate Minxiang Zeng (now assistant professor at Texas Tech University).

— Joan Fallon, College of Engineering